Designing the Ultimate Wall - Seawalls, Bulkheads or Retaining Walls

When you are working on a project that requires a wall, whether it is a water or non-water application, the Truline system should be in your tool box. It offers engineers and architects versatility in design and provides those constructing your design with installation flexibility, while providing long-term performance.

Walls, soil conditions, and site conditions all vary by project and even on the specific job site. Designing and building with Truline can save time and money and provide a low lifetime cost.

We work with many engineers and architects on various projects and can help answer any questions you may have along your design process. To get started, below is an introduction to designing with the Truline system and why it is beneficial.

3 General Installation Steps

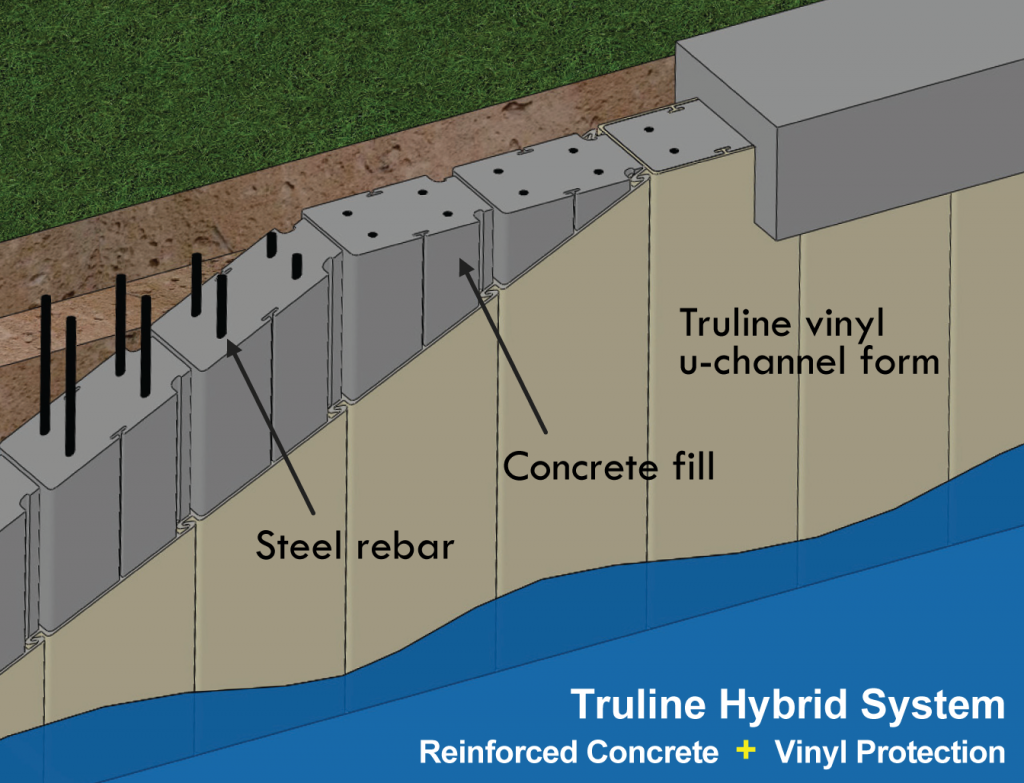

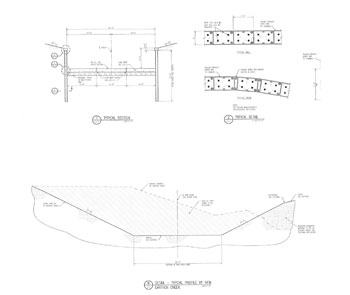

Many of the walls installed to date have been for water applications, such as seawalls, bulkheads or lake walls. These types of walls tend to have taller exposures, especially in areas where municipalities are requiring higher walls for tidal flooding and higher water levels. When the walls are taller, the Truline system with steel-reinforced concrete inside the forms is ideal for strength and loads. Generally, Truline walls can have an exposed height of 13 feet without wales being added to the front of the wall. In addition, for shorter exposures, other fill materials have been used and is engineering-acceptable. The 3 steps below show the general installation steps for a seawall.

1. Truline sheet pile parts are driven in the ground or to refusal. Soil plug removed.

2. The “cells” are filled with steel rebar and concrete. For rocky soil, a pin pile is installed.

3. Anchors and weep holes are installed along with a concrete cap.

Benefits of Designing Walls with Truline

The Truline wall system is unique. It is the latest innovation in seawall or retaining wall systems in over 30 years. Traditional materials of wood, aluminum, single-sheet vinyl, concrete, and steel have been installed for years now. They have known features, benefits and problems. See a comparison of 4 seawall materials.

Understanding these challenges and the need for a strong, good-looking and long-term performing wall system, Truline came to market. The Truline system combines the best of two proven materials, strong steel-reinforced concrete with the longevity and protection of vinyl sheet pile.

Engineering Firms: If your group would like a short in-house presentation on the Truline system, let us know. We would be happy to answer any questions and share our experiences.

RELIABLE PERFORMANCE

ASTM standards & third-party tested

We invested in testing the Truline product with a highly reputable and independent testing firm to ASTM standards so you can design with confidence. View the test data.

DESIGN WITH CONFIDENCE

Specifications based on actual test data

Not only are the specifications based on actual test data but we also had them analyzed by a third-party engineering firm. View the engineering specifications.

DESIGN VERSATILITY

Modular parts provide flexibility

Because the Truline system is comprised of modular parts, designs can include corners, curves, steps, hole cut-outs for pipes, and more to provide a complete and beautiful solution. Plus, Truline can span a 16 foot exposure without a waler. View the Truline parts and assembly.

INSTALLATION FLEXIBILITY

One system for various soils and projects

Truline is the "go-to" wall solution when you want it done right - one system for different types of residential or commercial projects - seawalls, retaining walls, and more. Truline can be installed in various soils and rock, even as the soil changes in each job site. View the installation options.

MADE WITH RECYCLED MATERIAL

Safe and environmentally-friendly with long-term performance

Made of over 92% post-industrial recycled vinyl material that is known to provide long-term performance and protection. Plus, the smooth flat surface provides a safe wall for animals or recreational activities on the water or sport courts. Additional eco-friendly advancements are currently being worked on to provide even more options.

STANDARD INSTALLATION METHODS & EQUIPMENT

Sheets up to 50 feet long installed

Depending on the depth of the wall, usually there is no need for heavy equipment that will cause more tear-up and cost. Truline can even be hand-carried and installed in small or tight job sites from land or water. For difficult soils or sheets longer than 20 feet, a Truline mandrel is available to drive the forms.

Generic Retaining Wall Design Process

Following are 6 basic steps to design a retaining wall. Download our guides for complete details with design examples.

1. Establish project requirements including all geometry and external loads.

2. Evaluate site subsurface conditions and determine relevant soil properties.

3. Determine load acting on the wall including lateral earth pressure distribution plus any external loads (surcharges).

4. Perform engineering analysis to determine required embedment depth (and unit anchor rod tension, if anchored wall) so that the resulting load and reactions satisfy the conditions of static equilibrium.

5. If anchored wall, design anchor system size and spacing and structural top cap with capacity to handle the unit anchor pull.

6. Calculate maximum bending moment acting on the wall and select a concrete reinforcing design whose factored moment capacity exceeds the maximum moment. Factored moment capacities are tabulated in the Truline design manual.

Engineers & Architects

Ready to add Truline to your design tool box? Questions on a current project?