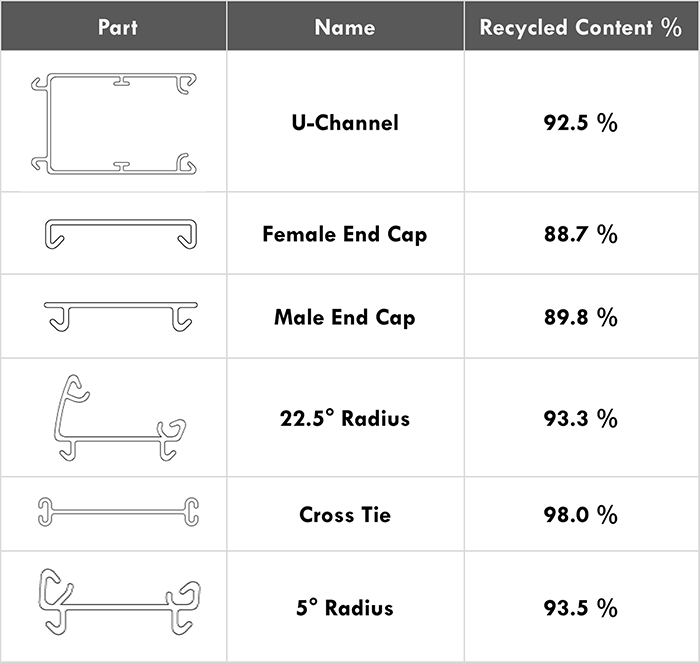

Product Information

Truline Modular Vinyl Sheet Piling Parts

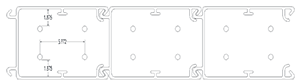

Below are the 5 Truline vinyl sheet piling parts available. The main u-channel part is 12” wide x 8” deep (304.8 mm x 203.2 mm) x custom length.

Each part is manufactured to custom lengths up to 40 feet (international container shipment maximum is 38 feet). View the engineering specifications for more detailed information.

Female End Cap

Slides onto the back of the U-Channel.

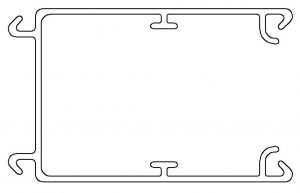

U-Channel

12" wide x 8" deep x custom length

Male End Cap

Slides onto the front of the U-Channel.

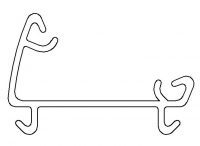

22.5º Radius

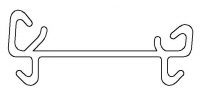

5º Radius

How the Truline Vinyl Sheet Piling Parts are Assembled

The modular Truline vinyl sheet pile parts are dual-interlocking and provide versatility in design, layout and installation. Essentially, the parts are slid onto each other with the open end sliding onto the closed back end.

Easy to Cut: The vinyl material is easy to cut on the job site if needed. Sometimes the length needs cut because rock is encountered in the soil and the part cannot be driven any more. When this happens, a pin is installed in the middle of the vinyl form and driven into the rock.

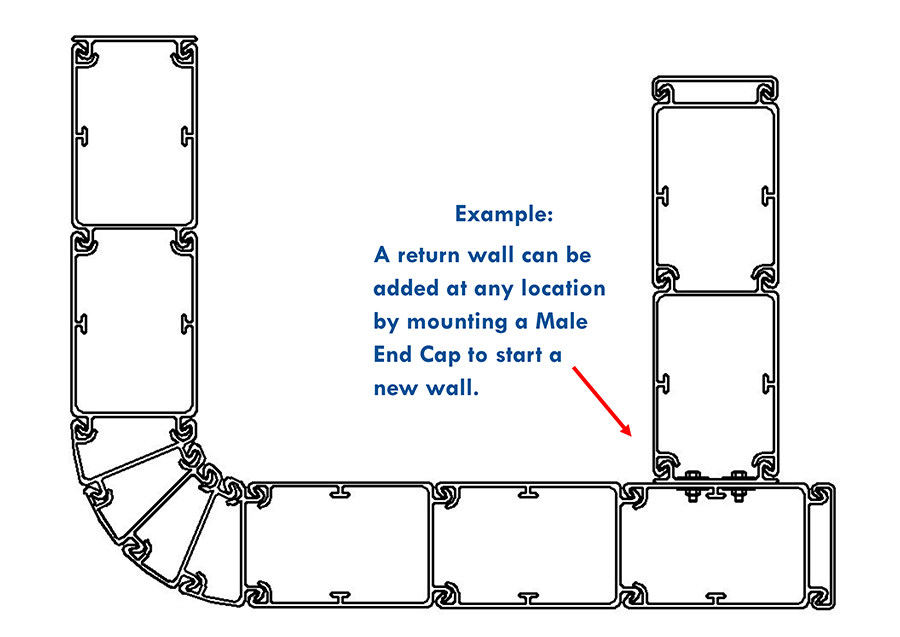

Easy to Build Corners and Curves: Corners and curves can be achieved with the two radius parts or with the limited flexibility in the dual locks (as shown in the photo) on all of the vinyl sheet piling parts.

Easy to Build Return Walls: Return walls or 90° degree corners can be placed at any location on the flat wall surface, as shown in the diagram below. Start a return wall by mounting a Male End Cap onto the first wall installed. See drawings for examples.

Have questions about your project?

Call (239) 422-6000 or submit a contact form.

The Ultimate Seawall® or Wall System: Steel-Reinforced Concrete Inside the Truline Form

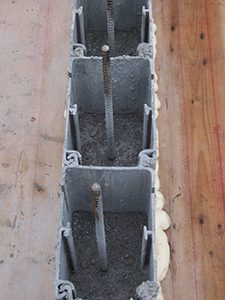

After the Truline forms are installed, the soil plug created inside the form is removed. Next, steel rebar is placed inside each form and concrete is tremie poured in place.

Engineers can design the wall with various steel rebar strengths and various concrete strengths depending on the load requirements and soil conditions. The drawings shown here illustrate the reinforced sections with 1 rebar, 2 rebars and 4 rebars. View the engineering specifications with the steel rebar and concrete strengths.

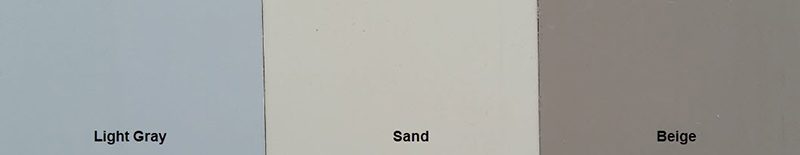

3 Standard Colors

All of the Truline vinyl sheet piling parts are available in 3 standard colors below or a custom color. Colors shown only provide an example and are not exact matches. Monitors and electronic devices will not show color accurately. Actual sample chips are available upon request. View more photos of the colors.

Over 92% Post-Industrial Recycled Material

Truline is made of an installed mix of 92.5% post-industrial recycled material content percent by weight. Since the U-Channel accounts for the vast majority of pounds used for any given installation, assuming no cross ties are used, the recycled content for the mix of products used in a typical wall is essentially the same as the recycled content of the U-Channel itself.