It is common to encounter shallow rock in certain areas that interfere with the installation of all common types of sheet pile other than steel. The rock is too hard to drive conventional steel alternatives like precast concrete, vinyl sheet or FRP through it. And the rock is shallow enough so that the layer of penetrable soil is not adequate to support the toe of a sheet pile wall on its own.

In many cases, while the rock is too hard for the systems mentioned, it is soft enough to drive steel sheet piling without predrilling. In such cases, steel has been the only sheet pile that could be installed economically.

Why Look for an Alternative to Steel?

Steel remains one of the most common materials found in seawall construction. Its high initial installation costs are often considered to be outweighed by its durability and versatility in terms of the size and height of the wall you can construct. However, while steel used in fresh water needs little maintenance, that is not the case in a saltwater environment. The greater maintenance, with its associated costs, has driven more companies to look for and use alternatives.

What Alternatives Are Engineers Left with?

Previously engineers would have needed to rely on steel sheeting in these situations. However, this is no longer the case. Innovation in seawall construction provides the strength and versatility of steel pile, without the negatives of high cost and continual maintenance. This is the Truline Sheet Piling System.

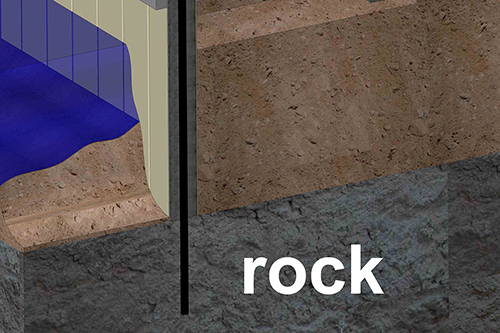

The system itself combines the use of steel pins, surrounded by concrete, all encased in Truline vinyl components.

The Truline cells are installed through the soil layer and set on top of the rock layer. The steel pins are then driven down into the rock anchoring the toe of the wall and concrete is poured into the cells, surrounding the steel pins and locking everything in place.

The whole system is easy for qualified contractors to install, requires very little in the way of maintenance, and has an expected lifespan of over 75 years. All of this is possible because the steel elements are not open to the corrosive effects of the saltwater. One further benefit of the system is that the entire construction sequence is performed above the water.

Does It Really Have the Versatility of Steel?

In many ways, the system is actually more versatile. Not only can each cell be created to your customer’s specifications in terms of size, but they are also available in different colors; Truline cells are produced in three standard colors, but can be manufactured in any custom color. The vinyl is UV-resistant as well, meaning that there is no discoloration or fading, even in the harshest of marine environments. Additionally, the vinyl is non-corrosive, does not chalk, and is resistant to chemicals.

As well as improving its appearance and life span, the system significantly reduces the impact of the saltwater seawall installation on the land and marine environments.