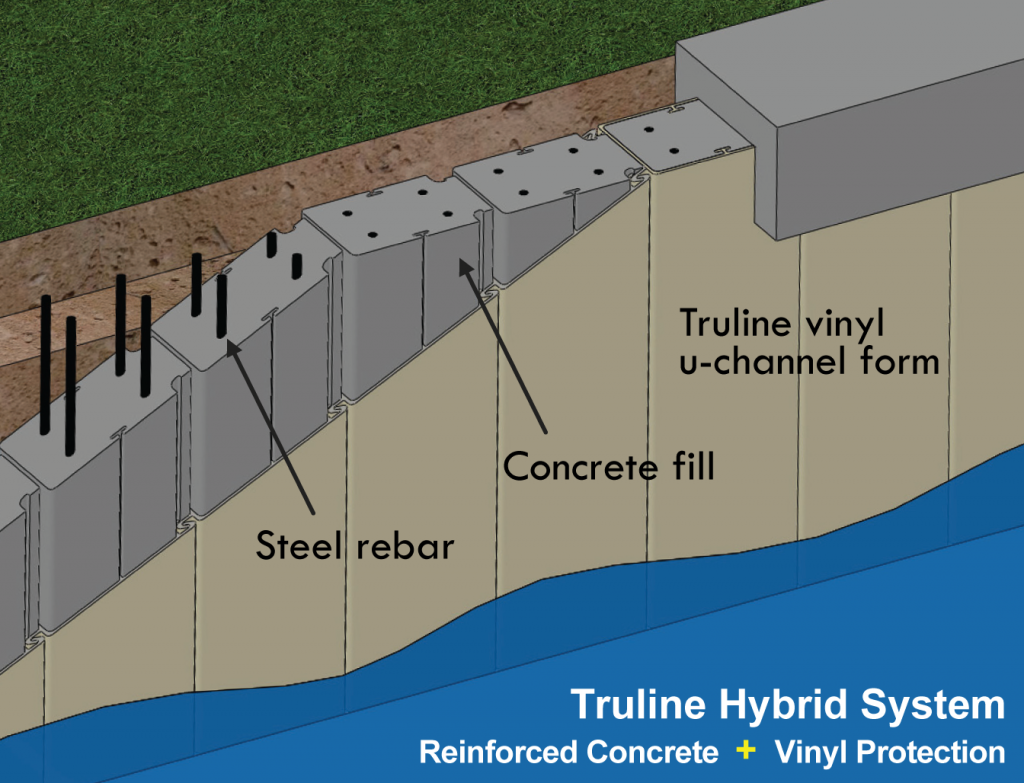

Installation Options for Seawall & Bulkhead Construction

There are typically two installation options for most seawalls or retaining walls. Most walls are either anchored or cantilevered (no anchor). The Truline system, however, is unique because it can be pin piled into rocky soil conditions.

This unique benefit of the Truline system helps engineers and contractors when installing a wall. Every job site is different and the soil conditions can vary during installation. Therefore, it is very helpful during the installation of any wall, to be able to pin pile individual sections in difficult or rocky soil conditions.

What does "pin pile" mean? Essentially, a steel pipe is installed in the middle of the Truline vinyl sheet pile form and driven into the rock, per the engineer's design. Walls that are not pin piled can end up "toeing out" at the bottom of the wall, which leads to failure.

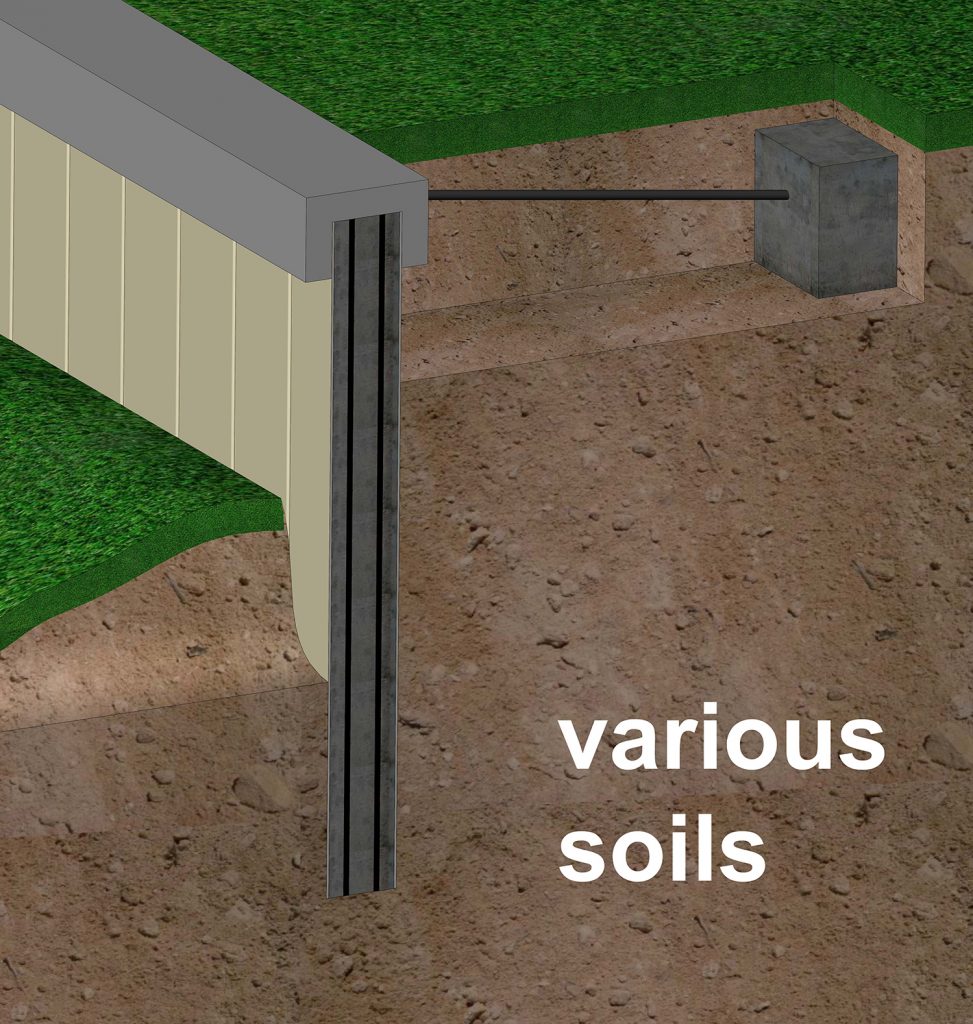

Anchor Installation

When conditions allow the sheet to be installed to the required depth for a stable wall.

- Use any tie rods and deadman or anchor systems.

- Walers can be used in place of or in addition to a structural top cap.

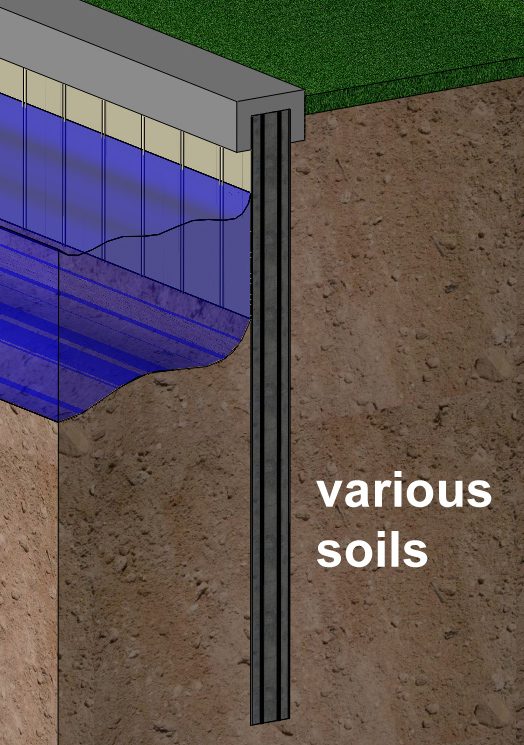

Cantilever Installation

When conditions allow the sheet to be installed to the required depth for a stable wall.

- Required embedment depths are deeper than needed for an anchored wall of the same height.

- Due to the stresses being much higher than for an anchored wall, the range of exposure height is also limited compared to the possible exposures of anchored walls using the Truline system.

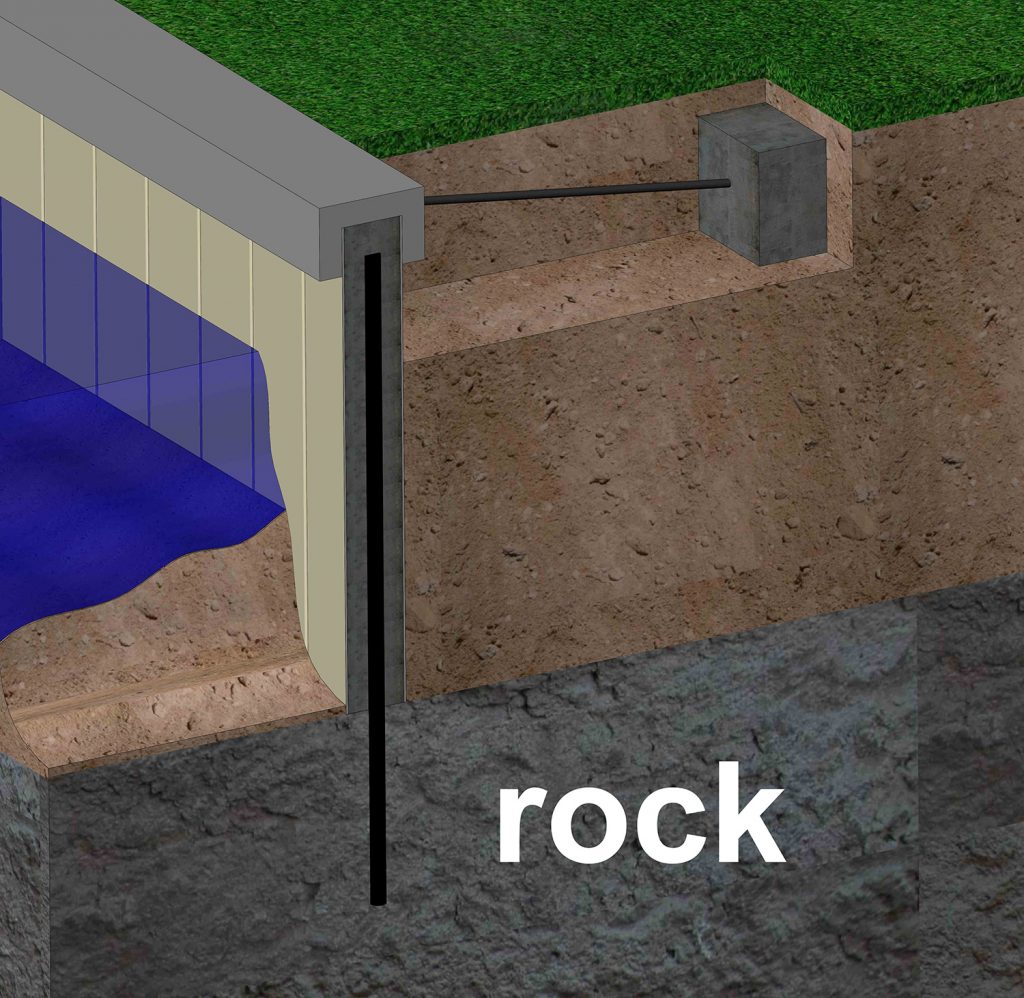

Pin Pile Installation

When conditions PREVENT the sheet to be installed to the required depth for a stable wall.

- Truline is first driven to refusal.

- A pin pile is then driven into the rock, extending below the toe of the sheet and up into the hollow of the Truline form.

Installing Truline

General steps and methods with standard equipment

Specifications

Engineering specifications with rebar and concrete tables

Product

Parts available, assembly, curves and turns, and colors