Test Data for Vinyl Sheet Piling

Truline vinyl sheet pile parts have been independently tested by a well‐known and respected firm, Intertek Group (formerly Architectural Testing, Inc.), that tests products for the largest building product manufacturers. According to Intertek, “for more than 130 years, companies around the world have depended on Intertek to help ensure the quality and safety of their products, processes and systems.” Three test reports are below:

- Load testing with concrete

- Load testing without concrete

- Salt Fog Exposure testing to analyze how Truline and the concrete inside the form perform in saltwater

Salt Fog Exposure Test

Performed by: Architectural Testing, Inc.

Report No.: C9598.02-106-31 (Nov. 2014)

Test Project:

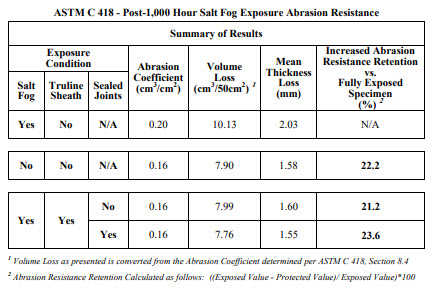

Perform a simulated seawater spray conditioning and post-exposure abrasion resistance evaluation on reinforced concrete piling specimens protected by Truline against a laboratory-conditioned control specimen and a fully-exposed control specimen consisting of the same reinforced concrete and subjected to the same seawater exposure without the benefit of Truline sheathing.

Test Methods:

ASTM G 85-11, ASTM C 1141-98 (2013), and ASTM C 418-12

Test Results Summary:

Truline-protected concrete, when exposed to accelerated saltwater testing performed as well as concrete that had no exposure. The test implies that Truline protection may nearly eliminate the damaging effects of saltwater on the surface of the concrete. The life expectancy of Truline-protected concrete is the same as the life expectancy of the same concrete in a non-marine environment. The typical life expectancy for reinforced concrete designed for the long term is 75+ years. Therefore, a properly designed and installed Truline cast-in-place reinforced concrete wall should perform at the same level.

Load Test with Reinforced Concrete

Performed by: Architectural Testing, Inc.

Results Analyzed by: Ensoft, Inc.

ATI Report No.: B7179.01-122-42 (June 2012)

Ensoft Report:

Interpretation of Testing Results on Truline Composite Sections

Test Project:

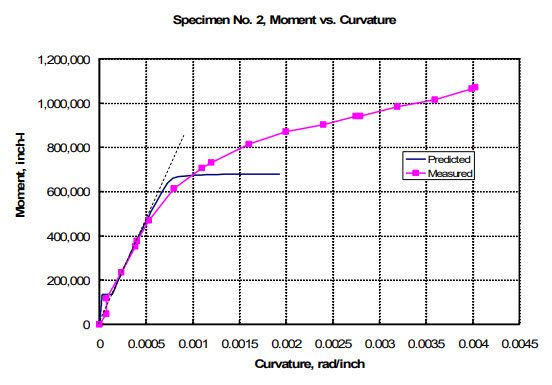

Validate predicted performance of Truline filled with reinforced concrete through independent testing and analysis.

Test Procedure:

Truline samples measuring 14 ft. long by 3 ft. wide filled with 3000 psi concrete and rebar were placed in 4 point loading ranging from 1000 to 40000 pounds while their center point deflections were measured for the given loads.

Predictions for the test performance for the as-built specimens were made using L-Pile software by computing moment curvature behavior for the material geometries and properties.

Test Results Summary:

An analysis showed that the predicted moment-curvature behavior closely matched the observed results. With the computational method validated, it could then be used with confidence to determine the moment capacities for the sections under many variations of concrete strength and reinforcing steel design.

Load Test without Concrete

Performed by: Architectural Testing, Inc.

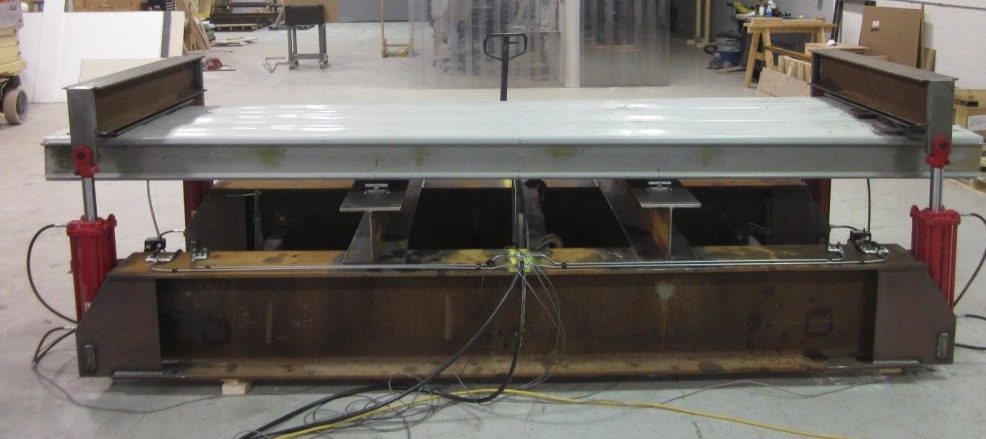

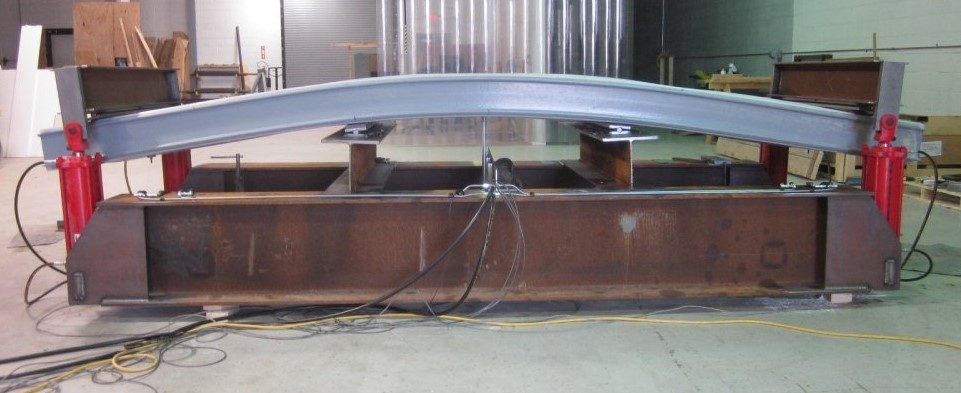

Report No.: 70174.01-122-44 (Feb. 2007)

Test Project:

Test the deflection and hydraulic pressure of Truline.

Test Setup:

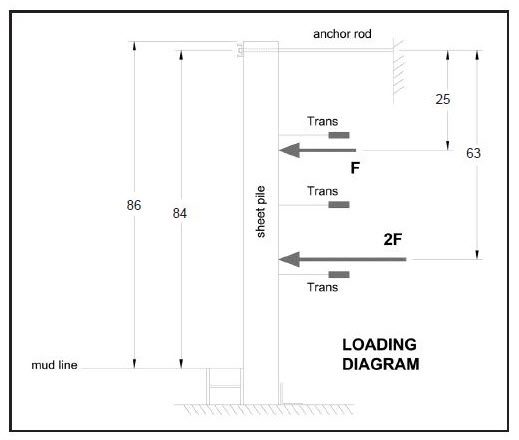

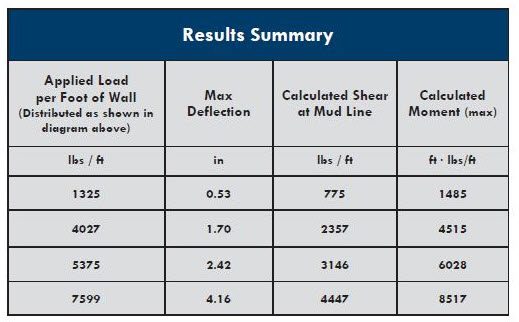

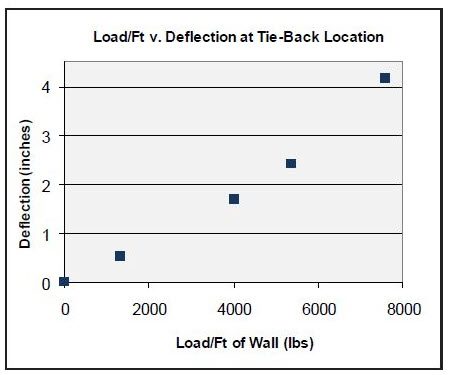

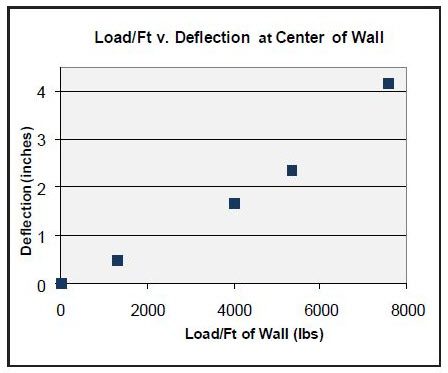

8 ft. high Truline wall (7 ft. above improvised mud line) with tie-backs, gravel fill and simulated concrete cap. Loading simulation was two rigid steel tubes placed 25 in. and 63 in. below the top edge. The top tube was loaded with two cylinders and the bottom tube was loaded with four so that the bottom load was always twice the top load. All cylinders were connected to a single manifold and pump so that they all generated equal force. (See Loading Diagram) The wall loaded to the desired level and held for one minute. The pressure was relieved and the wall was allowed to recover for one minute. After four loads were tested, the force on the wall was increased to levels that would exceed forces expected in real applications to observe and record performance data.