Concrete Seawall in Florida Keys Rocky Soil

Project: In the Florida Keys, where it is underlain by a shallow soft lime rock formation, it is very common to encounter the rock layer at depths where it interferes with placing the toe of a conventional concrete seawall to the depth required for a stable wall. Dealing with this problem was typically done in one of three ways. Undertake costly de-watering or underwater construction techniques to place lateral supports and earth anchors below the water line to stabilize the toe of a conventional precast concrete wall with an otherwise too-shallow embedment. A second option was to undertake those same costly underwater construction techniques and anchor a footing into the rock upon which a cast-in-place concrete seawall could be built. The third option was to use steel sheet piling which is strong enough to be driven into the soft rock but unfortunately has a high installation cost, high maintenance cost and a short service life in the harsh marine environment.

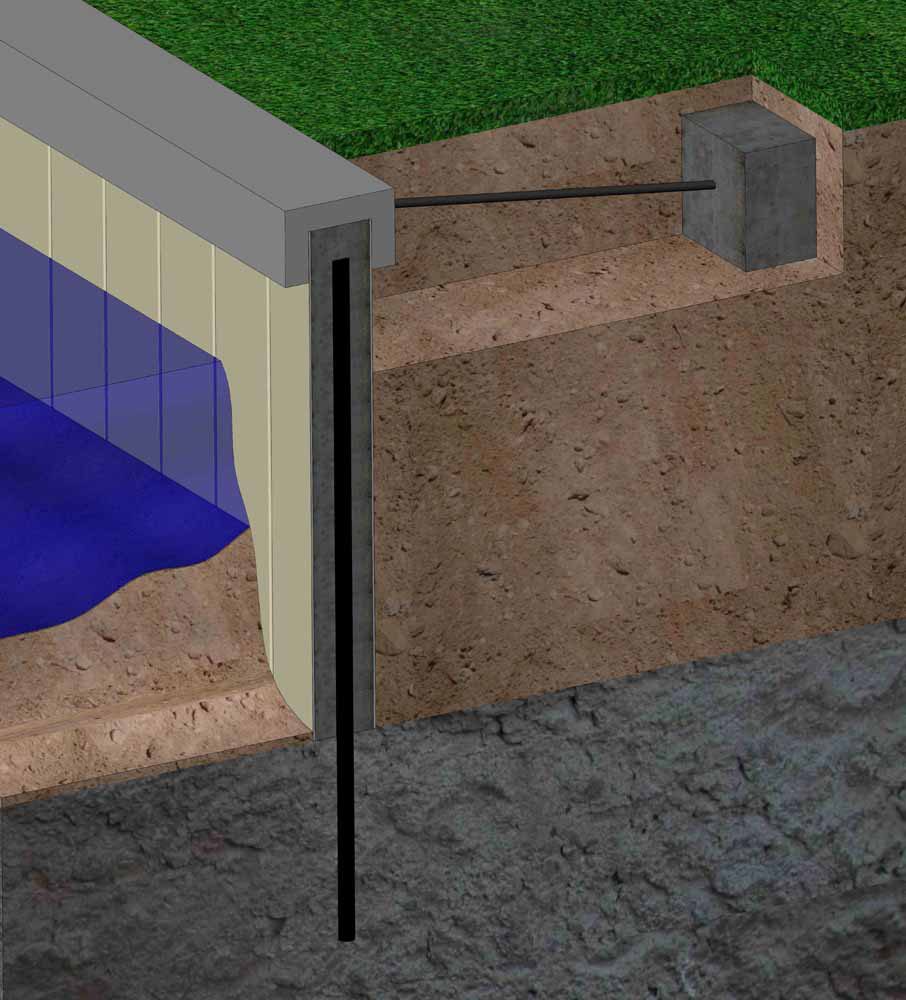

The Truline seawall system provides a better alternative with the pin-pile technique. Due to the unique nature of the system where the seawall is constructed as a series of hollow forms, the toe of the wall can be locked into the rock layer prior to pouring the concrete. This is accomplished by installing the Truline vinyl seawall panels to the depth of the shallow rock and then driving anchor pins down through the Truline form and into the rock layer. The pin locks the toe of the wall into the rock and when you subsequently place concrete into the Truline form, the wall is locked onto the pin. The entire construction sequence is done above water at a much lower cost and the resulting wall has a service life that is unsurpassed by any other wall system in the corrosive saltwater environment.

Cost Savings, Equipment and Installation: With minimal equipment needed, an 8000# mini excavator and 10’x24’ work barge, in addition to, little impact made to the previously developed upland area, installing Truline saved over 25% of the overall cost. All HDG rebar used, #8 centralized pin piles on 4 ft. centers and (4) #5 rebar used on all remaining cells. Jet Filters installed for drainage per engineer’s specifications. Truline radius parts used on all corners for continuous integrity and aesthetics.

Location: Big Pine Key, Florida

Engineer: Carl H. Schror, PE

Contractor: Lomrance Consulting

Length of wall: 500+ LF (800 series)

Length of sheet piles: 10 ft. +/-